The types of points that might be added consist of plating, increasing, circuitry, various sorts of hardware, installations, and spreadings. How these variables are added depends on the final application for which the item is created. In most cases, fabrication stores begin with a number of types of steels and create them into one piece. Fabricator stores start with several kinds of steels and develop them into one piece. This is a type of reducing that entails eliminating product from supply utilizing a device with a sharp suggestion or edge.

Exactly How Is Structural Steel Produced?

With a foundation in these concepts, you'll be well-prepared to take on nearly any type of layout and construction job. Some establishments worth taking into consideration are Imperial College London, the London Premier Centre and Nottingham Trent College ( short program in Advanced Structural Design). The manufacture of steel needs the purification of iron ore by removing its contaminations such as silica, phosphorus, and sulfur. Once the ore is detoxified, carbon is included in boost steel's toughness, stamina, and machinability. When speaking of steel, it is extremely common to interchange it with the word steel given that lots of people think that steel and steel are the same.

Florida Can Production-- Wintertime Haven, Fl

For the job to be finished in a timely manner, cautious preparation and organizing were called for. The monument works as an instance of how crucial it is to have a well-thought-out strategy and timetable for a steel production task. Even even more, structures and building modifications rely on successful welding for their success. Welding often changes rivet building because it transcends when it involves the stamina and toughness it offers frameworks. Besides that, since this procedure makes the alloy more robust and extra reliable, it indicates customers appreciate a good return on their investment. These business utilize this product in devices like pipelines, transmission towers, gas and oil wells, electromagnetic guards, photovoltaic panels, and electric power generators.

The metal supply is deformed according to the account of journalism or strike and the configuration of the supports or dies. Bending is generally made use of to develop metal sheets, plates, strips, rods, and bars. Its cutting device includes several reducing sides rotated against the steel stock. Drilling is commonly made with other machining procedures such as boring, trepanning, reaming, and countersinking.

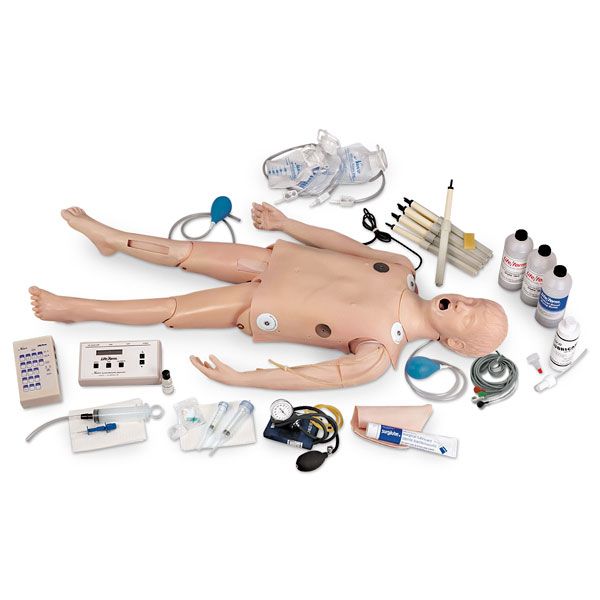

A lot of solid elements, such as gears, bolts, screws and nuts, are machined. The power industries rely on made architectural steel in the kind of transmission towers, wind turbines, pipelines, and oil and gas well platforms, to name a few. In the production market, architectural steel is used to produce platforms, steel ladders, commercial first aid training equipment stairs, mezzanines, steel hand rails, and more.

Structural Steel Fabrication Market Set to Hit USD 217.6 billion by 2031, Rising at a CAGR of 4.3 % Analysis by ... - GlobeNewswire

Structural Steel Fabrication Market Set to Hit USD 217.6 billion by 2031, Rising at a CAGR of 4.3 % Analysis by ....

Posted: Fri, 08 Mar 2024 08:00:00 GMT [source]

These scribes or marks should remain noticeable during the real fabrication. Common noting devices are metal scribers, pencils, chalks, dividers, and strikes. Besides the gauging devices, noting is aided by devices such as rulers, facility squares, and T-squares. The steel producing procedure is completed by trained steel makers that complete the cutting, flexing, and forming process. They are accredited and highly educated professionals that are educated in relation to the characteristics and residential properties of steel.

From the design phase to manufacture and erection, we ensure that our clients receive reputable and cost-efficient services that meet their particular needs. As a relied on companion in building, we prioritize security, efficiency, and consumer contentment. The steel fabrication process is a blend of sophisticated innovation, extensive experience, and talented metal fabricators and welders. The use of contemporary innovation boosts the efficiency, precision, and security of the general procedure. Modern advancements and automated equipment permit precise preparation, making certain each piece of sheet metal is made to exact specifications.

Any kind of project entailing the manufacture of steel must have a comprehensive plan and timetable in order to be successful. This includes preparing a strategy, establishing the devices and materials required, and developing practical completion days. A timeline and plan will ensure that the task remains on training course and that all parties are on the same page.

The producers, designers, and construction staffs will all interact to make sure that the framework is total, well-fitting, and solid enough to withstand the elements. With decades of experience fabricating architectural steel frameworks, you can rely on Swanton Welding to supply a top quality item for your next build. To learn more about our abilities, or for a quote, contact us today. Doing Steel is a leading architectural steel fabricator specializing in commercial construction projects. With years of experience and proficiency, we provide premium manufacture solutions to clients across numerous industries.

We benchmark ourselves to the vehicle sector and criteria to safeguard made the most of worth include for our customers as a true Tier 0.5 companion. We have procedures in several European and Asian Company Sites and Innovation Hubs, which are supporting our worldwide consumers. Our knowledge remains in industrial moderate, high-strength steel, put on immune and armored steel qualities. Straightening of warped steel weldments is performed with an oxyacetylene torch. In this highly specialized job, warm is precisely applied to the steel in a sluggish, direct sweep, causing the steel to contract towards the sweep as it cools.

CPR Depot

340 Croft Dr, Tecumseh, ON N8N 2L9, Canada

+15199462222